RELATED PRODUCTS

O PILE (SPSP)

Spiral

TRB

LSAW

ERW

SEAMLESS

Pipe Roofing

Seamless

Product introduction

Seamless piping manufacturing process begins as a solid cylindrical bar of steel called a billet. While still hot, billets are pierced through the center with a mandrel. Thereafter rolling occurs and stretches the hollow billet. The billet is precisely rolled and stretched until it meets the length, diameter and wall thickness as specified by the customer order.

Some seamless pipe types harden as they’re manufactured, so heat treatment after manufacturing is not required. Others do require heat treatment.

Advantages of Seamless pipes is the absence of any weld on the pipe. Though welded pipes can be fully tested, it still presents a possible weak point in the integrity of the pipe. Typically for certain applications that require particular straightness or tolerance requirements, will choose Seamless Pipes as the best option.

Hot manufacturing process of seamless pipes also allows for thicker pipes with smaller diameters to be achieved as compared to welded pipes which are limited to the bending of plates or coils.

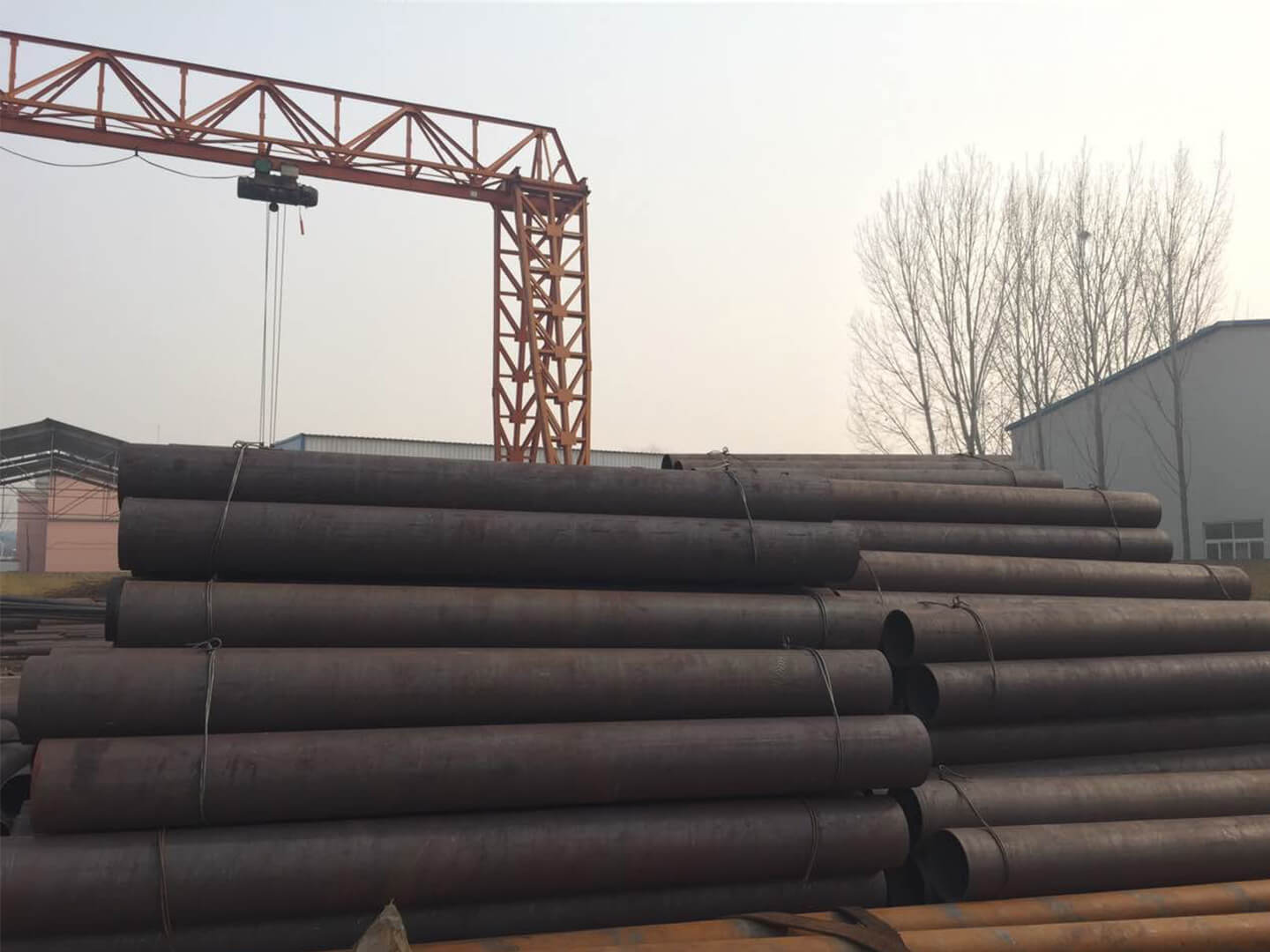

Product Images