RELATED PRODUCTS

O PILE (SPSP)

Spiral

TRB

LSAW

ERW

SEAMLESS

Pipe Roofing

Pipe Roofing

Product introduction

Interlocking Steel Pipe Roofing are commonly used in excavations and tunneling works which require minimal disruption to major services and roads. We have increasingly seen projects utilising such a method in Singapore as well as in built-up areas such as Hong Kong.

MLION CORPORATION has embarked on several projects in Asia providing interlocking pipe solutions. We are able to fabricate and deliver various interlocks as per design requirements.

MLION’S TECHNICAL ADVANTAGES

Reasons why engineers and designers now choose Mlion for Pipe Roofing:

- TRB Production: Three Rolled Bend pipes are the most ideal method for such production as we can ensure accuracy in pipe dimensions and straightness of the pipes. Spiral Welded pipes are not able to meet such strict tolerances required for such projects.

- Tolerances: We can control diameter of up to 0.5% from nominal value and wall thickness of up to +/-3%. Straightness can be controlled to achieve 0.2% of length or 3mm over any 1m distance. This allows splicing compatibility of pipes.

- Welding Fit ups: All our pipes are layed out in the factory to ensure the compatibility of interlocks and pipe dimensions. Alignment and readings are then taken before they are shipped out. This is to ensure Tunnel Boring Machine can function easily and succeeding pipes can be driven easily.

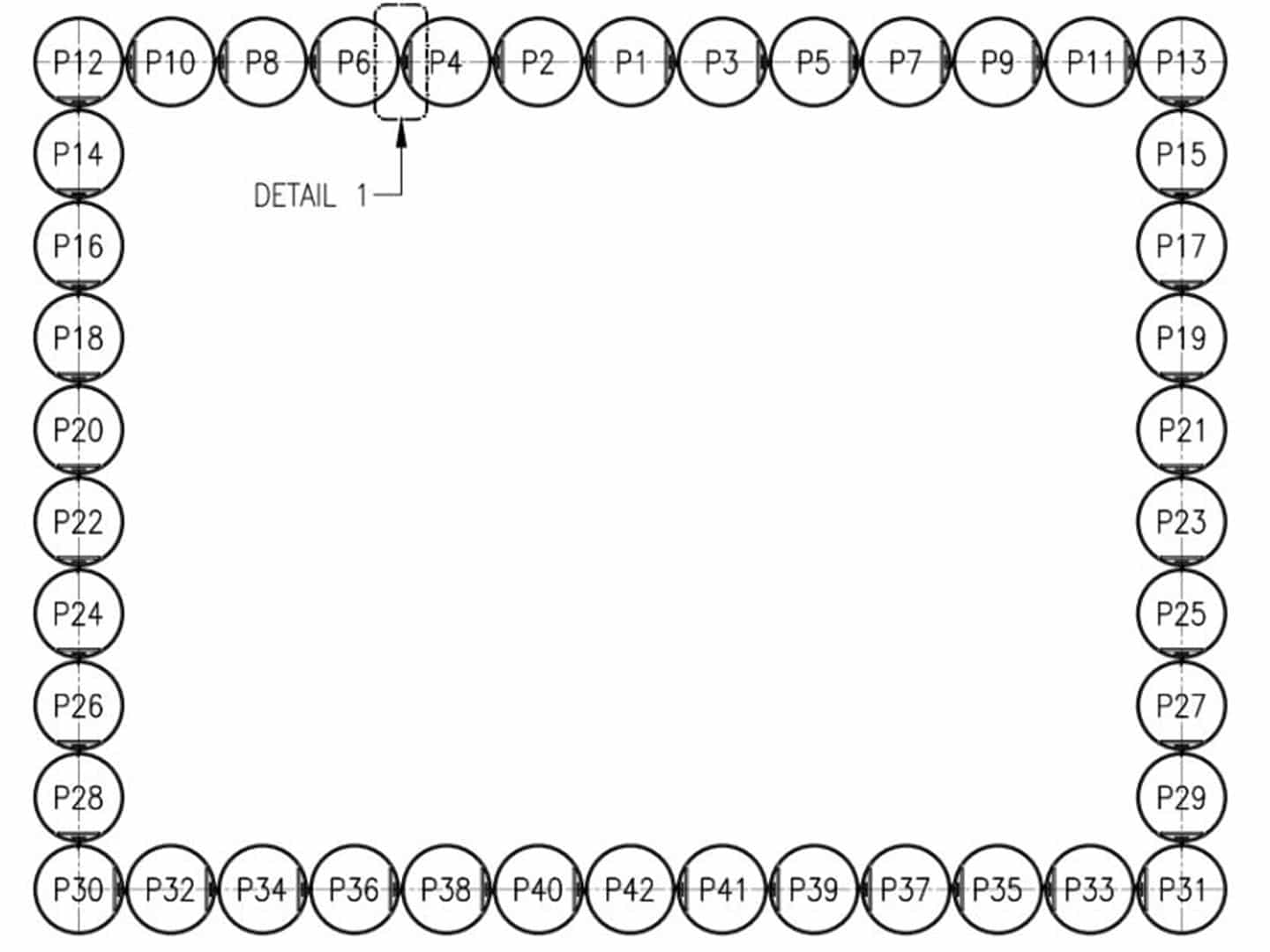

PIPE ROOF USING DTH HAMMER WITH

O-PILE DTH INTERLOCKS

An alternative method of installing a pipe roof is to use a Down-the-hole (DTH) Hammer which can be coupled with a O-Pile DTH Interlock. DTH method of installation gives greater speed as compared to Tunnel Boring Machine Methods.

O-Pile DTH provides the best interlocks to ensure straightness and drilling control during the boring process. The interlocks have been tested and proven successful in MTR Hong Kong projects through hard soil and rock conditions.

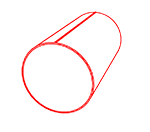

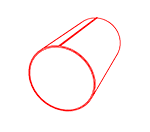

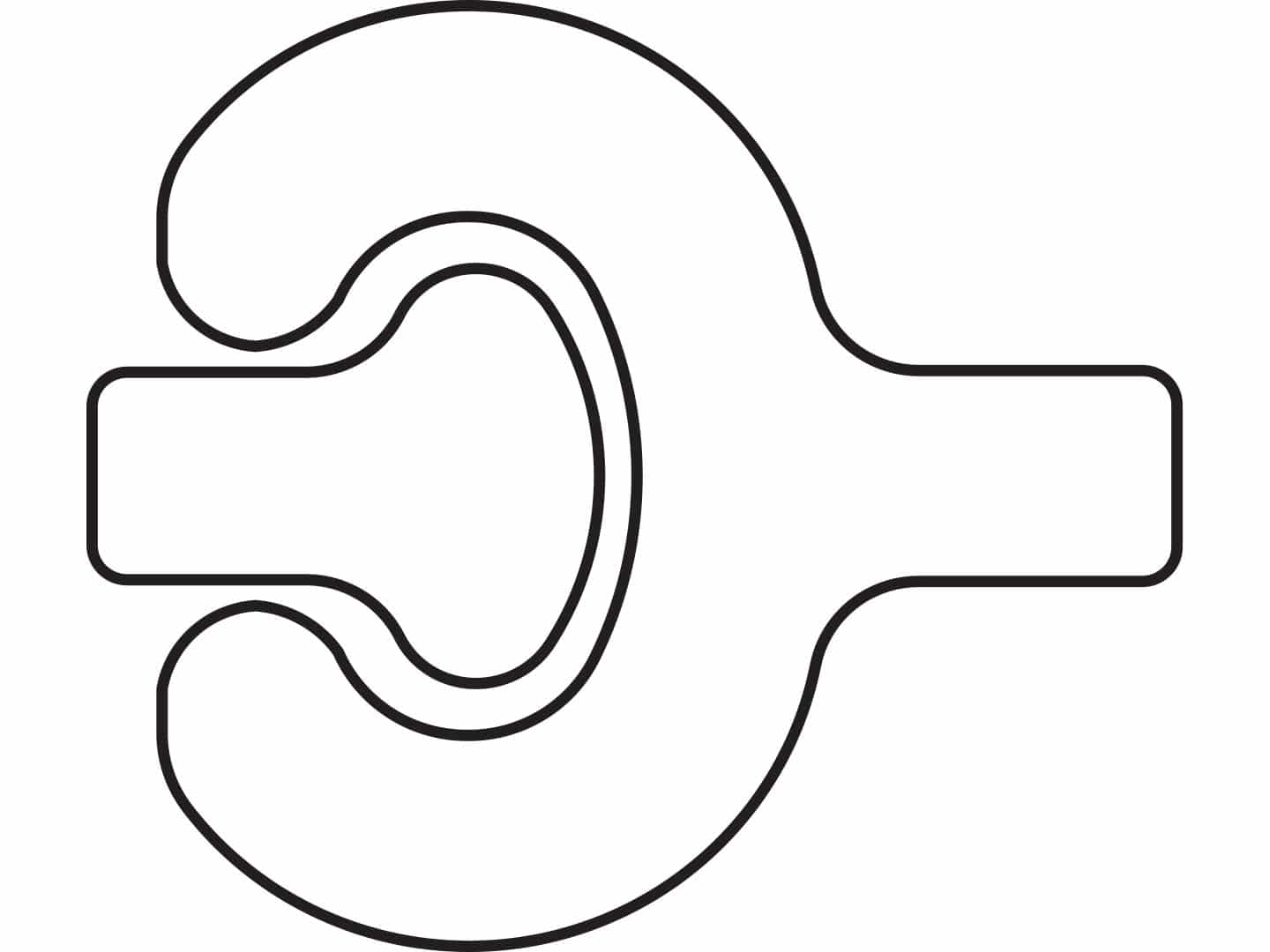

L-T Interlocks

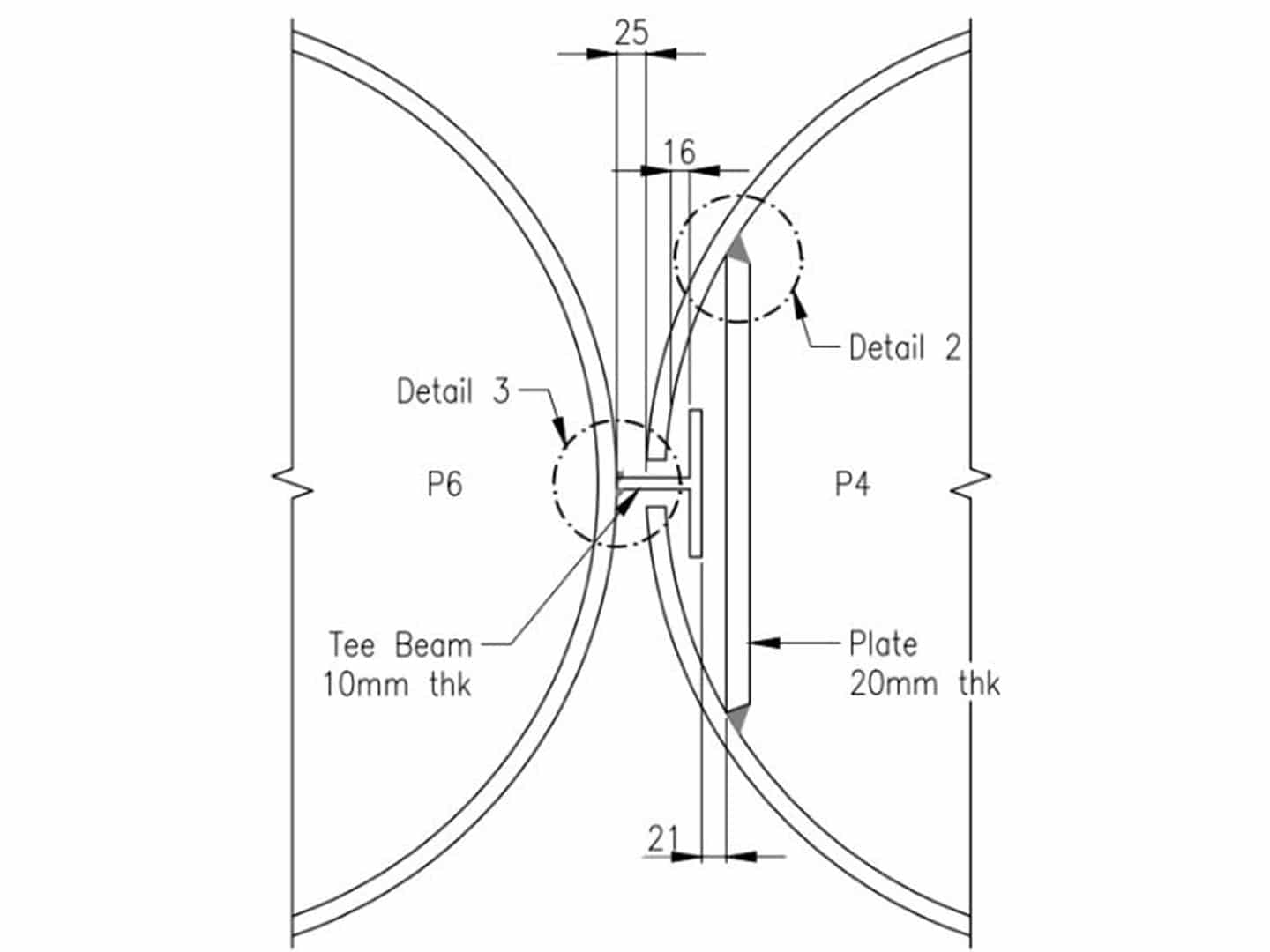

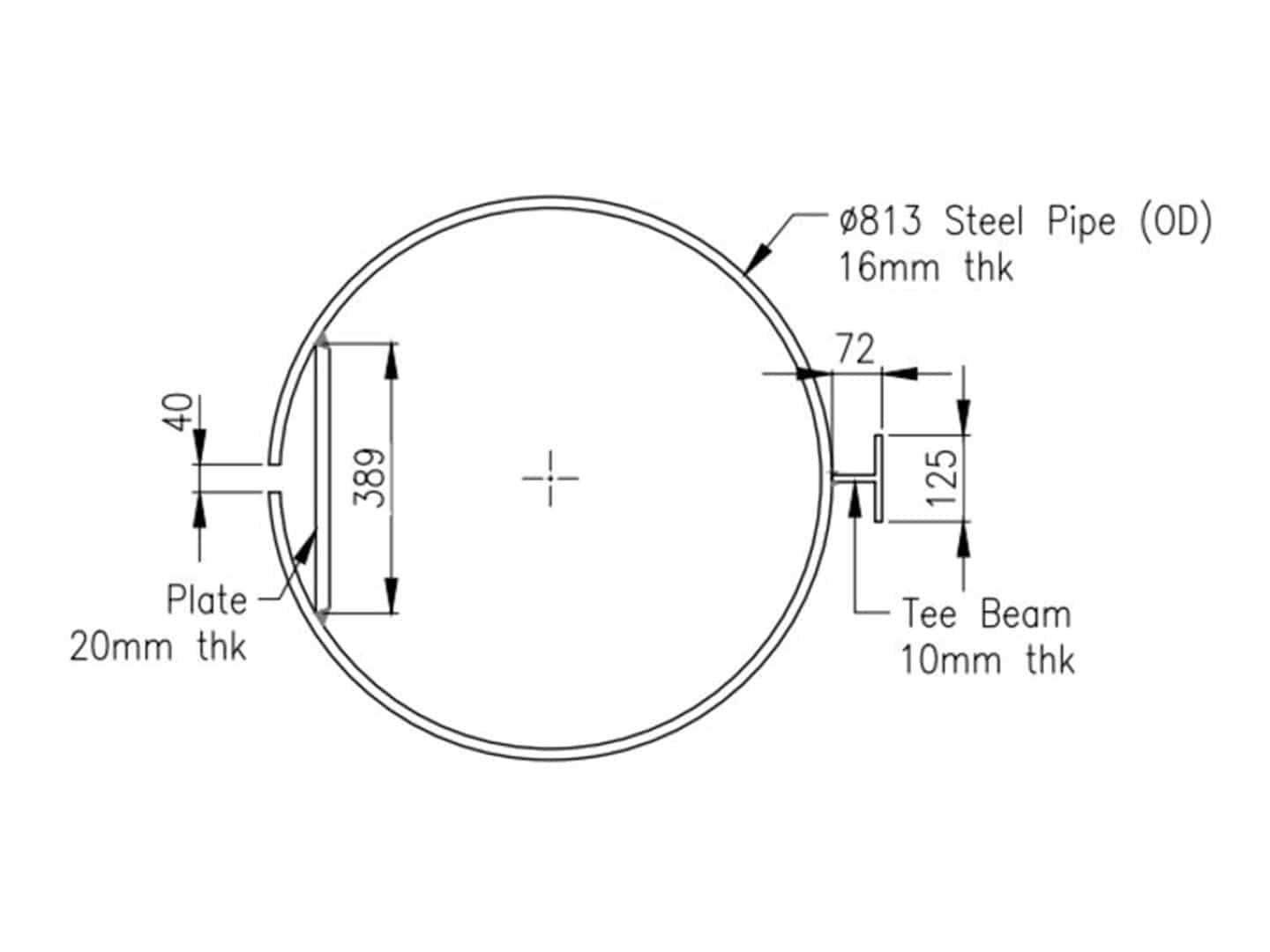

Typical Connection Details for mini-TBM

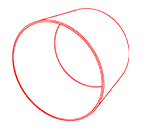

O-Pile DTH

(DTH Applications)

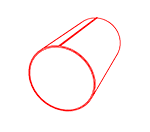

Tees

Plate Welding

Slitting of Pipe